GIEBEL Xdry®.

The strengths of silica gel & molecular sieve combined.

Soon we will deliver our adsorbers with GIEBEL Xdry®. The new filling makes our aeration dryers even more effective, because it combines the strengths of molecular sieve and silica gel orange-green.

While molecular sieve has a much stronger binding energy to polar substances, especially to water, silica gel orange scores with its very high water absorption capacity.

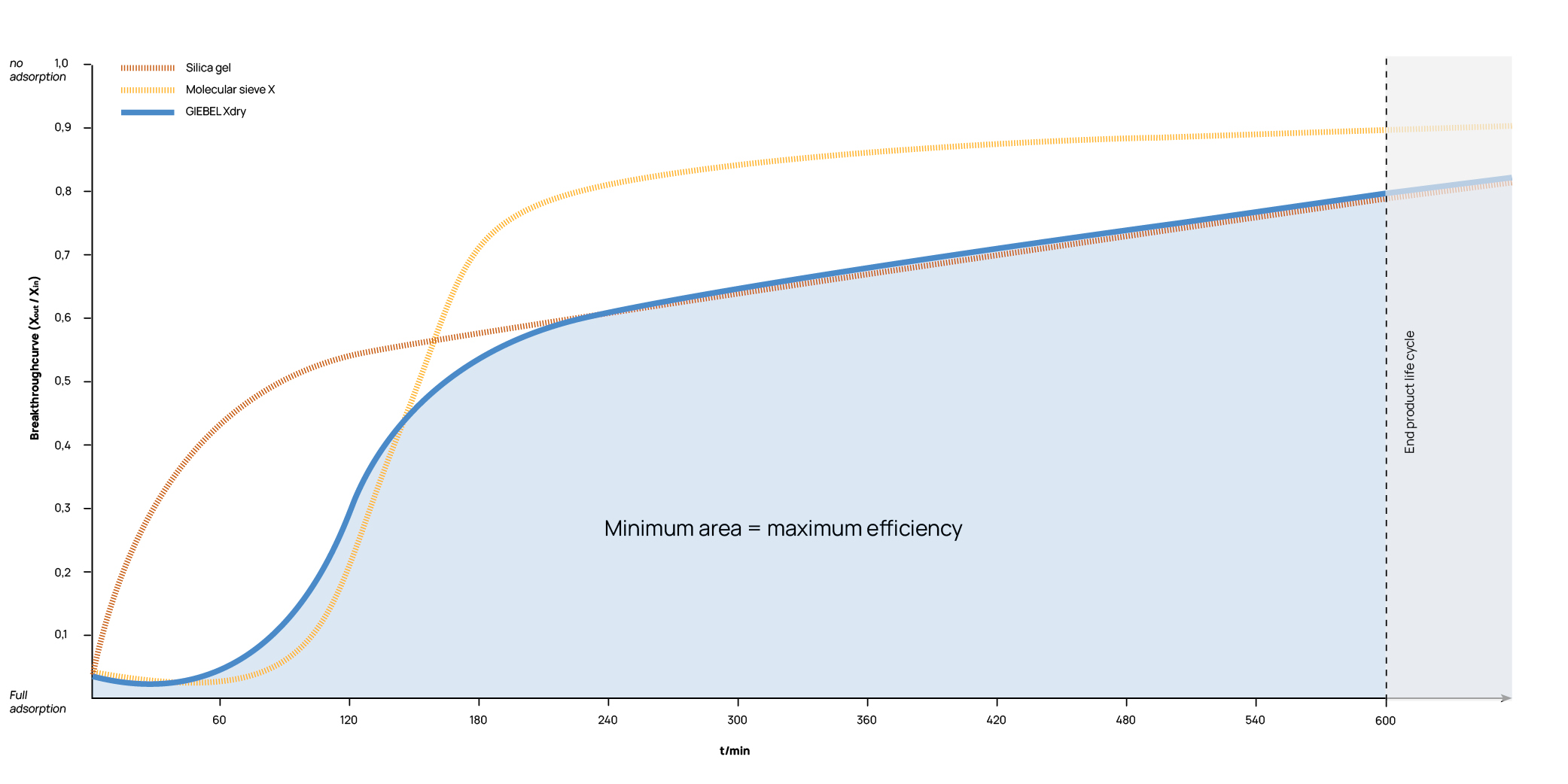

The drying curve of GIEBEL Xdry® shows that at the beginning the mixture keeps the residual moisture of the outflowing air very low, like Molecular Sieve, and that with increasing loading it becomes more similar to the curve of Silica Gel. Thus, an adsorber filled with GIEBEL Xdry® binds a higher percentage of moisture until its color changes to green and your plant remains even better protected.

The advantages of GIEBEL Xdry® at a glance:

- Use at higher temperatures

- Use at lower humidities

- Stronger drying of the sucked in air and thus less humidity in the plant

- Safe use & easy disposal

GIEBEL Xdry® compared to silica gel.

GIEBEL Xdry® has a maximum water absorption of 35% at 100% RH and 20°C in the climatic chamber – silica gel therefore appears at first glance to be the more suitable desiccant with a maximum water absorption of 40%. In practice, however, an adsorber is already fully loaded and colored green at a water absorption of 33% of the dry mass. The initial humidity of the air flowing through is then approx. 35% RH. The fact that GIEBEL Xdry® has the lower maximum water absorption therefore does not come into play when used in an aeration dryer.

Graphic 1: Breakthroughcurve

A similar picture emerges when considering the drying performance. Up to a load of 25%, less moisture flows out of an adsorber when it is filled with GIEBEL Xdry® instead of silica gel. This shows: more water remains in the adsorber. At a loading of 25% to 35%, both materials behave approximately the same.

At a loading of 35%, the end of the product life cycle of an adsorber is reached. If the adsorber were to be operated further, GIEBEL Xdry® would be at a disadvantage compared to silica gel. In both cases, however, a plant would then no longer be sufficiently protected. The replacement of the adsorber at a loading of 35% is therefore urgently recommended.

Graphic 2: Residual humidity after loading

How do I recognize that I have to exchange an adsorber filled with GIEBEL Xdry®?

Replace your adsorber as before when a complete color change of the silica gel grains from orange to green has taken place. GIEBEL Xdry® and silica gel have the same color change point and therefore the same maintenance interval.

How much water does GIEBEL Xdry® absorb?

The maximum water absorption capacity of GIEBEL Xdry® is 35% of the dry weight. At a loading capacity of approx. 33%, the adsorber is completely discolored green and must be changed. For practical purposes, the loading capacity of 33% is therefore relevant.

The following shows the loading curve. Here, too, it can be seen that GIEBEL Xdry® combines the advantages of silica gel & molecular sieve.

Graphic 3: Loading process

The proportion of water that flows through the adsorber into the system is significantly lower than with pure silica gel. GIEBEL Xdry® thus adsorbs a higher proportion of water from the air drawn in and thus protects the plant to be ventilated more effectively.

The proportion of water entering the plant is between the drying performances of silica gel and molecular sieve.

Graphic 4: Water entry after loading

The following figures show that there are no changes in the maintenance interval compared to an adsorber filled exclusively with silica gel. The adsorber is replaced after complete green coloration and reaches a water absorption of 33% and an initial residual humidity of 35% RH.

GIEBEL Xdry® – 0% Loading

GIEBEL Xdry® – 10% Loading

GIEBEL Xdry® – 20% Loading

GIEBEL Xdry® – 30% Loading

Silica gel – 0% Loading

Silica gel – 10% Loading

Silica gel – 20% Loading

Silica gel – 30% Loading

The perfect mixture for GIEBEL Xdry® ?

In tests with various mixing ratios and molecular sieves of different grain sizes, it has been shown that an increase in the silica gel content always leads to a reduction in drying performance. An increase in the molecular sieve content, on the other hand, has a negative effect on the water absorption capacity and shortens the maintenance interval of an adsorber. For our aeration dryers, a different mixing ratio would therefore prove disadvantageous.

To ensure that our adsorbers provide the best possible drying performance for you, GIEBEL Xdry® consists of silica gel orange-green as well as a molecular sieve with X structure and Na+ cations with an effective pore size of 10A.

At which humidities is GIEBEL Xdry® used?

Ventilation dryers are usually used at humidities of 60-100% RH. At this humidity the risk for condensation in your installations is highest. The higher isotherm of GIEBEL Xdry® at lower humidities (see figure) allows the use also in dry environments. Thus, use is already possible at 30% rH to further dry air flowing through.

Graphic 5: Isotherme

At which temperatures can GIEBEL Xdry® be used?

The temperature application range GIEBEL Adsorber® is extended by the change to the new desiccant. Since the regeneration temperature of silica gel is 120°C, the water absorption of silica gel is already limited at 80°C. Molecular sieve, on the other hand, has a constant water absorption up to about 250°C and is not regenerated until 300°C.

At temperatures above 80°C, adsorption with GIEBEL Xdry® is taken over by the molecular sieve contained. Until the molecular sieve is completely loaded, adsorbers with GIEBEL Xdry® can therefore also be used at temperatures above 80°C.

How can GIEBEL Xdry® be regenerated?

Due to the different regeneration temperatures of the silica gel and molecular sieve contained in the GIEBEL Xdry® , we do not recommend regeneration of the desiccant. If silica gel is heated to over 120°C, the color indicator it contains burns out and turns brown. Temperatures below 250°C, on the other hand, have no significant effect with regard to the regeneration of molecular sieve.

The bed of our adsorbers filled with GIEBEL Xdry® is therefore replaced after complete loading. For this purpose, you can obtain practical refill packs of GIEBEL Xdry® in various sizes from us.

Is GIEBEL Xdry® harmful to health?

The components silica gel orange and molecular sieve are classified as non-hazardous substances according to the law of the European Union (Regulation EC No. 1272/2008). They are not subject to mandatory labeling according to the EC Directive (67/548/EEC or 1999/45/EC).

GIEBEL Xdry® is thus also classified as a substance that is not hazardous to health or the environment.