The MA-RV series.

Reusable adsorber with valves for indoor & outdoor use according to ATEX

GIEBEL Adsorber® of the MA-RV series are multi-way aeration dryers with valves. They are suitable for indoor and outdoor use on hydraulic power packs, gearboxes, storage tanks and mobile machinery.

The all-aluminum housing is filled with GIEBEL Xdry®. The desiccant mixture ensures effective drying of the supply air. A 3 μm filter additionally cleans the intake air. When air is forced out of the system, a layer of activated carbon adsorbs escaping oil mist, thus protecting the desiccant and the environment from contamination. When the adsorber is saturated, both desiccant and all other components of the internal system can be replaced at low cost if necessary. MA-RV adsorbers are used for aeration of aggressive materials as well as in harsh environments. The aeration dryers are available with FKM or EPDM seals and can be used in zone II 2 G / D IIC T4 according to the ATEX product directive 2014/34/EU.

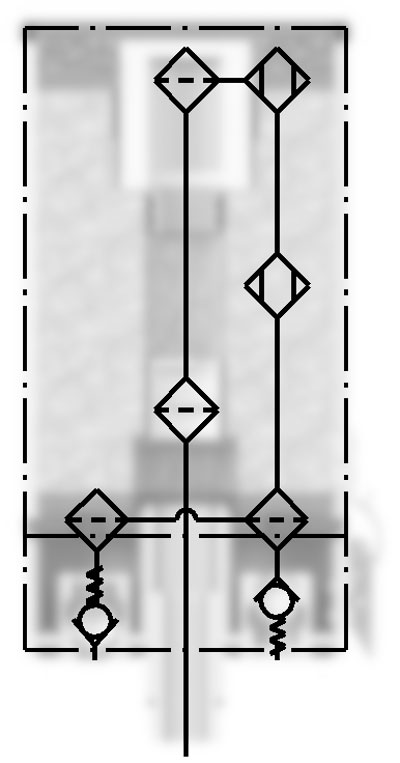

Mode of operation.

Adsorption – drying of the supply air

- Fill level of the system decreases

- Humid air is sucked in

- Valves open at approx. 6 mbar

- Uniform flow through the adsorber

- Air is dried to 2% rH

- GIEBEL Xdry® discolors as saturation increases

- Air is filtered to 3μm

Dry and clean supply air

Desorption – separation of oil particles

- The level in the system rises

- Dry, oily air is squeezed out

- Activated carbon absorbs the oil mist

- Dry, oil-free air regenerates the desiccant

- GIEBEL Xdry® partially recovers its color

Self-regeneration and oil-free exhaust air

Technical data.

Flowchart

The sucked air opens the valves in the lower part of the adsorber at approx. 6 mbar. After flowing into the adsorber, the air is evenly distributed over the cross-section. The pre-filter disc frees the air from coarse dirt particles.

When flowing through the desiccant, the water molecules are reliably removed from the air. The gap volume of the granulate is optimally selected with 2 to 5 mm grain size and guarantees a minimum pressure build-up with simultaneously very good drying performance. Thus, at the beginning of the drying process, a residual air humidity of max. 2% rH and a dew point of -40°C will be achieved. A 3µm filter ensures that all dirt particles are separated from the ambient air and the GIEBEL Xdry® fill and that the connected plant is not contaminated.

When air is discharged, a two-stage slosh protection and a layer of activated carbon prevent oil droplets, oil particles and oil mist from entering the desiccant, thus enabling the adsorber to self-regenerate.

As saturation increases, the orange silica gel grains of the GIEBEL Xdry® fill turn green. If the silica gel grains have turned completely green, the packing must be replaced. After 4-5 replacement cycles at the latest, we also recommend replacing seals, particle filters and activated carbon discs.

Pressure ratios.

Spare parts kits.

Sustainability starts with using product components for as long as their life cycle allows and replacing only those components that show signs of wear. With our spare parts kits for the refillable adsorber series, we ensure that you can replace each individual component of an adsorber as needed.

For example, the desiccant in our adsorbers becomes stressed over use, increasingly loses its ability to adsorb moisture and needs to be replaced, while the adsorber housing is particularly durable. Our refillable adsorbers can therefore be easily opened and the desiccant replaced. Seals, particle filters and activated carbon disks can withstand a few replacement cycles, depending on the load. However, we recommend replacing them after 4-5 replacement cycles at the latest to ensure smooth operation of the adsorbers.

Our spare parts kits include gaskets, particle filters, activated carbon discs and other components matched to the respective adsorber series. The matching desiccants for the adsorbers are available separately and in different sizes.

| Adsorber | Spare parts kits |

|---|---|

| MA-RV 2L | ET MA-R 2 ET MA-R 2 EPDM |

| MA-RV 3M MA-RV 3L |

ET MA-R 3 ET MA-R 3 EPDM |

| MA-RV 5M MA-RV 5L MA-RV 5XL |

ET MA-R 5 ET MA-R 5 EPDM |