The VV-D Series.

Disposable breather dryers, developed to protect hydraulics, gears, drums and IBCs as well as mobile machinery with constant air exchange and short maintenance intervals in indoor, outdoor and offshore use against moisture damage.

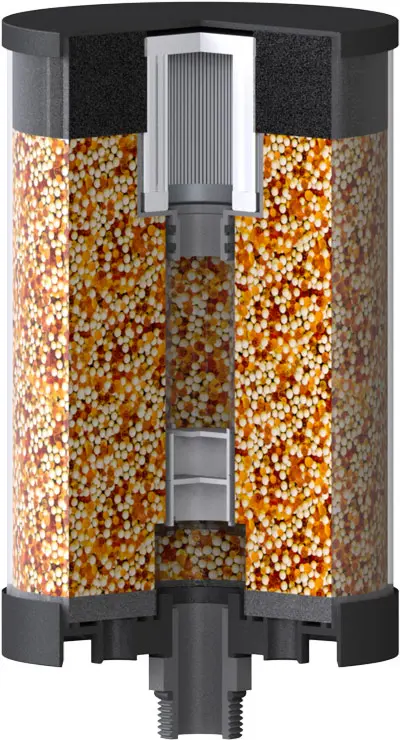

The plastic housing is filled with GIEBEL Xdry® and also has a 3μm filter to ensure effective drying and cleaning of the supply air. A layer of activated carbon adsorbs escaping oil mist when the air is pressed out of the system to protect desiccant and environment from contamination. Once the adsorber is saturated, it is replaced.

Downloads.

Mode of operation.

Technical data.

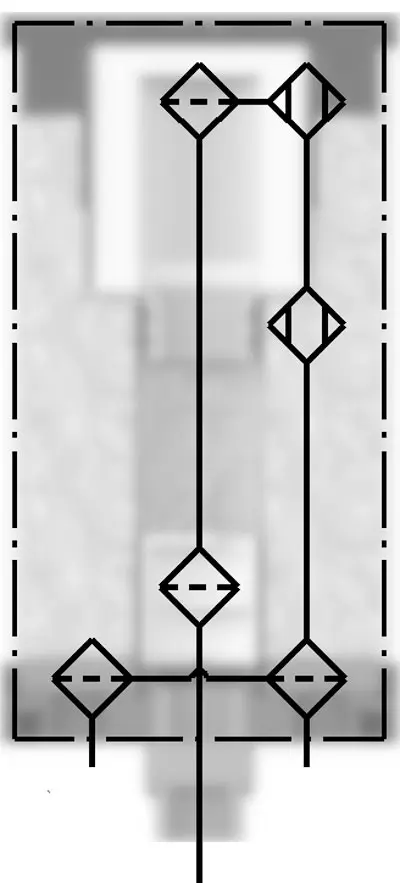

Flowchart

The sucked-in air flows through the openings in the lower part of the adsorber almost without pressure. The air is then evenly distributed across the cross-section. The pre-filter disc frees the air from coarse dirt particles.

When flowing through the desiccant, the water molecules are reliably removed from the air. The gap volume of the granulate is optimally selected with 2 to 5mm grain size and guarantees a minimum pressure build-up with very good drying efficiency at the same time. Thus, a residual air humidity of max. 2% rH and a dew point of -40°C are achieved at the beginning of the drying process. A 3µm filter ensures that all dirt particles are separated from the ambient air and the GIEBEL Xdry® fill and that the connected plant is not contaminated.

When air is discharged, a two-stage slosh protection and a layer of activated carbon prevent oil droplets, oil particles and oil mist from entering the desiccant, thus enabling the adsorber to self-regenerate.

With increasing saturation, the orange silica gel grains of the GIEBEL Xdry® fill turn green. If the silica gel grains have turned completely green, the adsorber must be replaced.

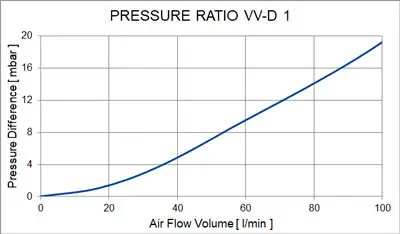

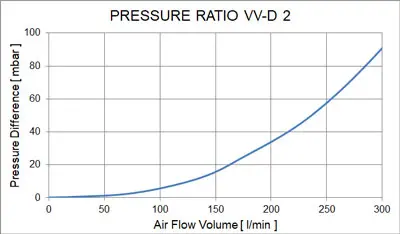

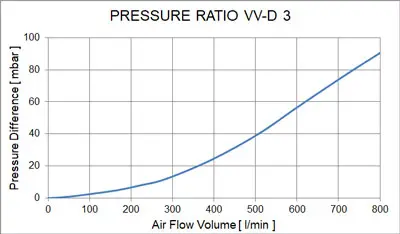

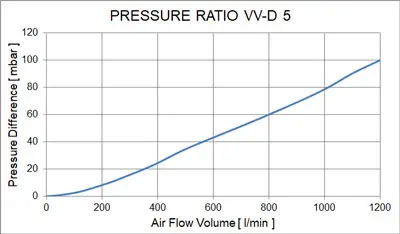

Pressure ratios.

Replacement cartridges.

Currently, no replacement cartridges are available for the VV-D series. Here, the complete adsorber is replaced after complete saturation.