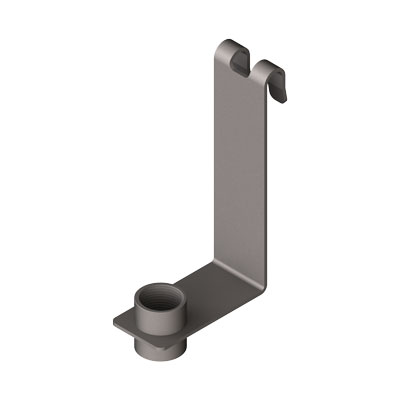

MA-R 3M G1″m

The MA-R 3M is a dehumidifier / ventilation dryer with a refillable aluminium cartridge without valves. The adsorber is suitable for indoor and outdoor use according to ATEX and is available with FKM or EPDM seals. Thanks to a 3μm filter, the sucked in air is also completely cleaned and an activated carbon layer adsorbs oil mist to protect the desiccant and the environment from contamination. With a capacity of 0,85kg of GIEBEL Xdry®, it adsorbs up to 298ml of water until the color of the desiccant changes.

With the G1″m connection, this product is suitable for use on mobile hydraulics.

Product Code: MA-R_3M_F_00_P3_XC_G1m

Item Number: 05.0040.02

EAN: 4260611134723

Datasheet

349,00 € (plus VAT)

You need large quantities? Please contact us so that we can provide you with an individual offer.

Products that match your selection

Product Description

| Weight | 2,11 kg |

|---|---|

| Adsorbent | GIEBEL Xdry® |

| Adsorbent weight | 0,85kg (GIEBEL Xdry®) |

| Max. water adsorbtion until color-chance | 298ml |

| Filter fineness | 3µm |

| Adsorber Size | 3 |

| According to ATEX 2014 / NEC505 | Yes |

| Connections | G1"m |

| Corrosivity | C4 |

| Country of origin | Germany |

| Customs tariff code | 84213925 |

| Handling | Rechargeable |

| Housing | Aluminium |

| Installation | Standing (Standard) |

| IP Protection Class | IP 63 |

| Operating environment | Indoor / below deck, Outdoor / on land |

| Sealing | FKM |

| Substance in container | Class 1: Hydraulic oil, gear oil, biological oil, vegetable oil, transformer oil, AdBlue (urea), diesel fuel, isocyanate, polyol, anhydrite, Class 2: Gasoline, kerosene, acetic acid, polyethylene glycol, isopropyl alcohol, diethylene glycol |

| Temperature | -40°C .. +80°C / 160°C |

| UV resistance | Very high |

| Valves | No |